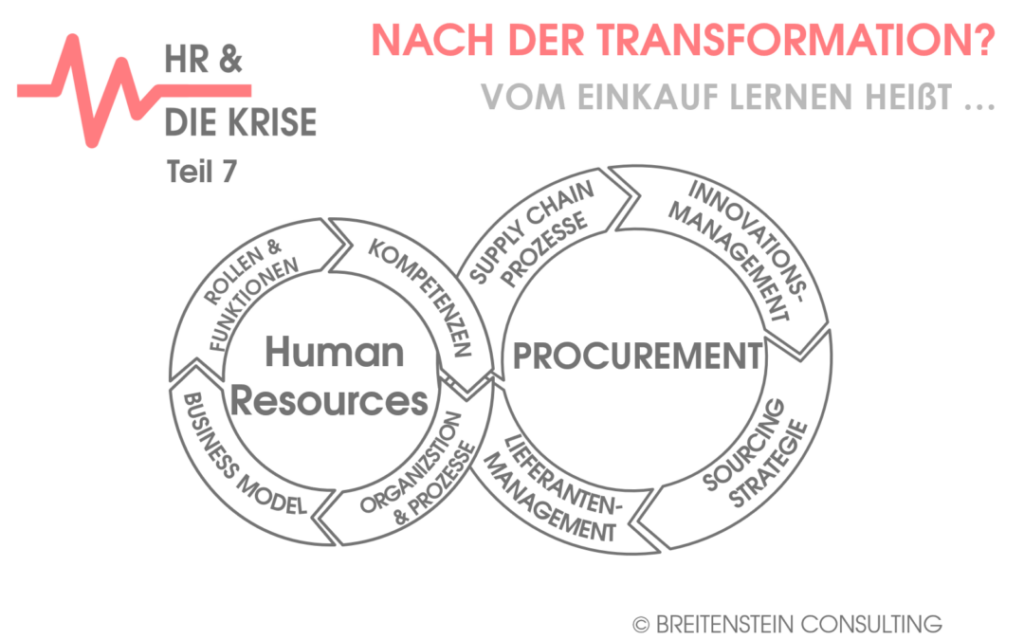

Human Resources is facing major challenges that will change the function. In the two previous articles, I described how strategic workforce management will affect the skills requirements for HR.

In the discussions that followed, I was asked: What comes next… When we have transformed everything? Where is the workforce of the future?

I had the pleasure of working for almost 8,500 employees in purchasing and supply chain for a corporation for five years, among other things in HR. Even then, I thought to myself: we in HR could learn a thing or two from how purchasing designs its field of work!

I will explain here what that could be specifically.

The boundaries between inside and outside are blurring

First of all, a hypothesis:

There are many indicators that suggest that the boundaries between inside and outside an organization are becoming increasingly blurred:

Despite all efforts and proactive workforce transformation, the pressure to adapt to technological and social change will never be fully met with existing personnel. The increasing division of labor in many industries is constantly reducing the depth of added value. The home office experience of the last few months is pushing employees further away from the feeling of “belonging”. I know many people who also see this as an opportunity for autonomy. Digitalization is creating new value chains – entire highly specialized industries are emerging – such as AI consulting and data analysis as a service. Outsourcing, concentrating on core competencies and flexibly purchasing expertise and workforce is becoming more obvious and easier. Increasing digitalization is bringing more and more transparency to markets. This will create more differentiated demand.

For companies, this has many advantages

Companies will become more flexible and less dependent on fixed costs through the skillful management of various resource pools. Those who manage to seamlessly integrate external and internal resources will simultaneously tap into great innovation potential. In the ‚classic‘ industry, we have always looked enviously at the automotive companies. We had 50% real net output ratio – they had up to 80%. When an automobile manufacturer builds a new car, the supplier delivers the entire dashboard with all mechanical and electronic components to the assembly line. And they not only built it – but usually also developed most of it themselves – in close development cooperation with the supplier industry.

Managing ecosystems of resources

I believe that the future of human resources will be to actively manage various ecosystems of resources. What we are doing today, such as occasionally using contract workers and consultants, is just a very small first step in that direction. In the future, we will have to manage an organization’s strategic skills needs through the systematic management of just as strategically selected resource pools. And the challenge here is no longer just to find these pools on international markets, but to develop and retain them in a similar way to a company’s own workforce. The big tech companies in Silicon Valley are already doing this with their developer communities. A company’s own employees must be focused on core competencies. And there is no room for error here – just as the automotive industry has overlooked the importance of battery technology. Teams of suppliers, consultants, or universities must be able to work together just as effectively as if they belonged to the same organization. The management of affiliation, corporate identity, competencies, intellectual property, performance and benefits must be consistent. Terms of employment must be able to adapt to market developments. Leaders must be able to effectively reach and motivate not only their own employees, but also ‚foreign‘ employees. Our German labor and collective bargaining laws, which are strongly geared towards affiliation, are not particularly helpful in this regard. If HR organizations want to take on this strategic task, then there needs to be a complete rethink here about what human resources are and how they are managed!

Learning from procurement

Modern, strategic procurement organizations have developed strategies, competencies and an understanding of their role that can be used for orientation:

- End-to-end: strategically aligned purchasing organizations think in terms of complete value chains, from the initial innovation to after-sales service and spare-parts policy.

- Early involvement: In order to have this broad perspective across all stages of the value chain and to be able to decide how suppliers can be integrated, purchasing must be involved from the outset.

- Sourcing strategies: Today, purchasing organizations must have a good knowledge of supplier markets and their maturity on a global scale in order to find the right suppliers and retain them. Risk management always plays a role here to avoid becoming dependent on just one supplier.

- Negotiation strategies: Similar to sales, purchasing has developed sophisticated negotiation strategies to be able to price services and to leverage economies of scale for larger quantities. Incidentally, a small myth is dispelled here: the days of a Mr. Lopez, in which the buyers of automotive companies ‚fleeced‘ small suppliers to the point of collapse and shifted all risks to them, are over. Most buyers I know pursue a very symbiotic supplier strategy.

- Supplier management: Although cost transparency, e-sourcing, e-bidding, etc. are standard tools, in most ‚mature‘ markets, co-development, cross-company teams, mutual appreciation and respect are part of the culture of working with suppliers. Suppliers are systematically included and the employment relationship is systematically managed using a variety of tools. This ranges from compliance and risk issues along the entire value chain to account management, in order to maintain the relationship on both sides and avoid disruptions.

- Innovation management: As already mentioned, in mature industries, more innovations often come from suppliers than from your own company. 8 out of 10 is a figure that is always in the room. To systematically exploit the full innovation potential of specialized supplier markets, purchasing must itself be deeply involved in the matter (including technically).

- Make or buy: In my opinion, we have arrived at the crux of the matter here. An effective purchasing organization (as in the automotive industry) must be involved in the decision as to whether internal or external resources are to be used for a product. This shows how important the role of purchasing is as a function at the decision-makers‘ table.

What can HR learn from this?

First of all, I think it’s a question of attitude as to whether a human resources function feels it has overall responsibility for the area of salaried employees. Then there’s the question of whether you, as an HR professional, really understand your own business strategy well enough to be able to make informed decisions about make-or-buy.

Then you have to know your own supplier base well – and that goes far beyond temporary employment agencies, interim management and consulting firms. Where do we need core competencies as an organization – and where don’t we? You have to be able to derive these competencies from the business strategy. Incidentally, this is a ‚by-product‘ of workforce transformation.

HR organizations can learn a great deal from their purchasing colleagues in terms of supplier market analyses, sourcing and negotiation strategies, and contract management. And there are a multitude of opportunities for cooperation between purchasing and human resources. However, this requires a different, more open attitude. Purchasing and HR are very close in many respects. Both are supplier functions that together represent almost 100% of a company’s production factors.

Ultimately, the aim is to create ecosystems together so that people – regardless of their organizational or other background – feel comfortable, are treated fairly and a climate is created in which they can work together on an equal footing, free of hierarchy. This is where the human factor counts!

At least in this field, the strength of human resources should lie, from which perhaps purchasing can also learn something.

My team and I have supported purchasing organizations with HR concepts on multiple occasions. Why not transfer the experiences of purchasing to the HR organization the other way around?